This product features a fully custom, made-to-measure design tailored exclusively to you. The result is a truly unique fit — as if it were sculpted directly onto your body.

About the Suit

Intrudair Student Suit – Professional Training Jumpsuit for Skydiving Schools

The Intrudair Student Suit is an essential piece of equipment for every skydiving school and is trusted at some of the world’s leading dropzones.

Research & Development at the Highest Level

Our student suit is the result of an extensive research and development process. Through hundreds of test jumps, with the involvement of numerous professional skydiving instructors, and the collaboration of textile experts and technicians from the Óbuda University of Light Industry, we have optimized and refined every detail. The knowledge and experience gained from this process have been directly integrated into the design, ensuring the suit meets the strictest safety and training requirements of skydiving schools.

International References

The reliability and quality of the Intrudair Student Suit are proven by its presence at major dropzones worldwide, including Skydive Dubai, Skydive Chicago, Skydive Madrid – and many others where safety and professionalism are top priorities.

Professional Features

- Reinforced Cordura on knees and seat for maximum durability.

- Extra-strong grips, designed to meet even the strictest AFF training requirements.

- Optimized cut for student comfort, safety, and ease of instruction.

Backed by 20 years of experience in skydiving suit manufacturing – our customer service team assists in selecting the right sizing and configuration based on your school’s geographic location and specific needs.

Benefits for Schools

- Innovation born from research & development

- Enhances student safety and the professional image of your school

- A reliable, long-term investment

The Intrudair Student Suit is more than just a training jumpsuit – it is the result of a comprehensive development process, combining the expertise of instructors, engineers, and technicians.

Intrudair Student Suit – Professional Training Jumpsuit for Skydiving Schools

The Intrudair Student Suit is an essential piece of equipment for every skydiving school and is trusted at some of the world’s leading dropzones.

Research & Development at the Highest Level

Our student suit is the result of an extensive research and development process. Through hundreds of test jumps, with the involvement of numerous professional skydiving instructors, and the collaboration of textile experts and technicians from the Óbuda University of Light Industry, we have optimized and refined every detail. The knowledge and experience gained from this process have been directly integrated into the design, ensuring the suit meets the strictest safety and training requirements of skydiving schools.

International References

The reliability and quality of the Intrudair Student Suit are proven by its presence at major dropzones worldwide, including Skydive Dubai, Skydive Chicago, Skydive Madrid – and many others where safety and professionalism are top priorities.

Professional Features

- Reinforced Cordura on knees and seat for maximum durability.

- Extra-strong grips, designed to meet even the strictest AFF training requirements.

- Optimized cut for student comfort, safety, and ease of instruction.

Backed by 20 years of experience in skydiving suit manufacturing – our customer service team assists in selecting the right sizing and configuration based on your school’s geographic location and specific needs.

Benefits for Schools

- Innovation born from research & development

- Enhances student safety and the professional image of your school

- A reliable, long-term investment

The Intrudair Student Suit is more than just a training jumpsuit – it is the result of a comprehensive development process, combining the expertise of instructors, engineers, and technicians.

Intrudair specialises in full custom-made tailoring. Whether it's a skydiving suit, a tunnel suit or a wingsuit, Intrudair always makes them fully custom made. We believe that decades of custom-made tailoring experience cannot be exchanged by a proportionately zooming software. It can help but cannot replace the working experience of skilled tailors who have a massive knowledge of different body shapes and their characteristics. Our tailors have gained experience in making over 10,000 custom made garments since we started our operations. This solid base helps to form the backbone of our wingsuit sizing.

The human body structure can vary greatly from one size to another, so our colleagues cut and sew the prototypes needed for the basic measurements very carefully, this is ESSENTIAL before we launch a product. It may slow down the release of the product a little but it guarantees that we work with accurate fitting patterns.

When you receive an Intrudair wingsuit, you can be sure that our experts have checked your measurements and tailored your wingsuit to your size according to the closest fitting pattern to you. We cannot always be 100% accurate but we guarantee that when you order a custom Intrudair wingsuit, it will be made specially for you.

The shape of the wingsuits is becoming more and more streamlined in each category- see the experiments of the early 2000s (since when we talk about modern wingsuits) or the evolution of the shape of the parachute canopy.

The secret is in the details, the different profile heights and shapes determine the main flight characteristics of the suit. The most typical glide ratio and speed in each category set the direction of development.

LEADING EDGE:

Intrudair uses a special, three-layered, slightly elastic, laminated material (developed just for this purpose) for the leading edge. It keeps its shape and adapts to the position of the arm, depending on whether you use soft foam or special performance foam.

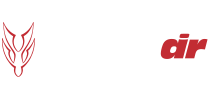

PERFORMANCE FOAM:

We use a profile-cut foam in the new Intrudair wingsuit that does not restrict free movement but holds the outside of the leading edge firmly in place while taking up and levelling the shape of your arm inside. It is easy to replace and does not break.

The amount of air entering the air intakes determines the pressure in the wings. Although this is adjustable, Intrudair puts a lot of effort into experimenting with different sizes of air intakes.

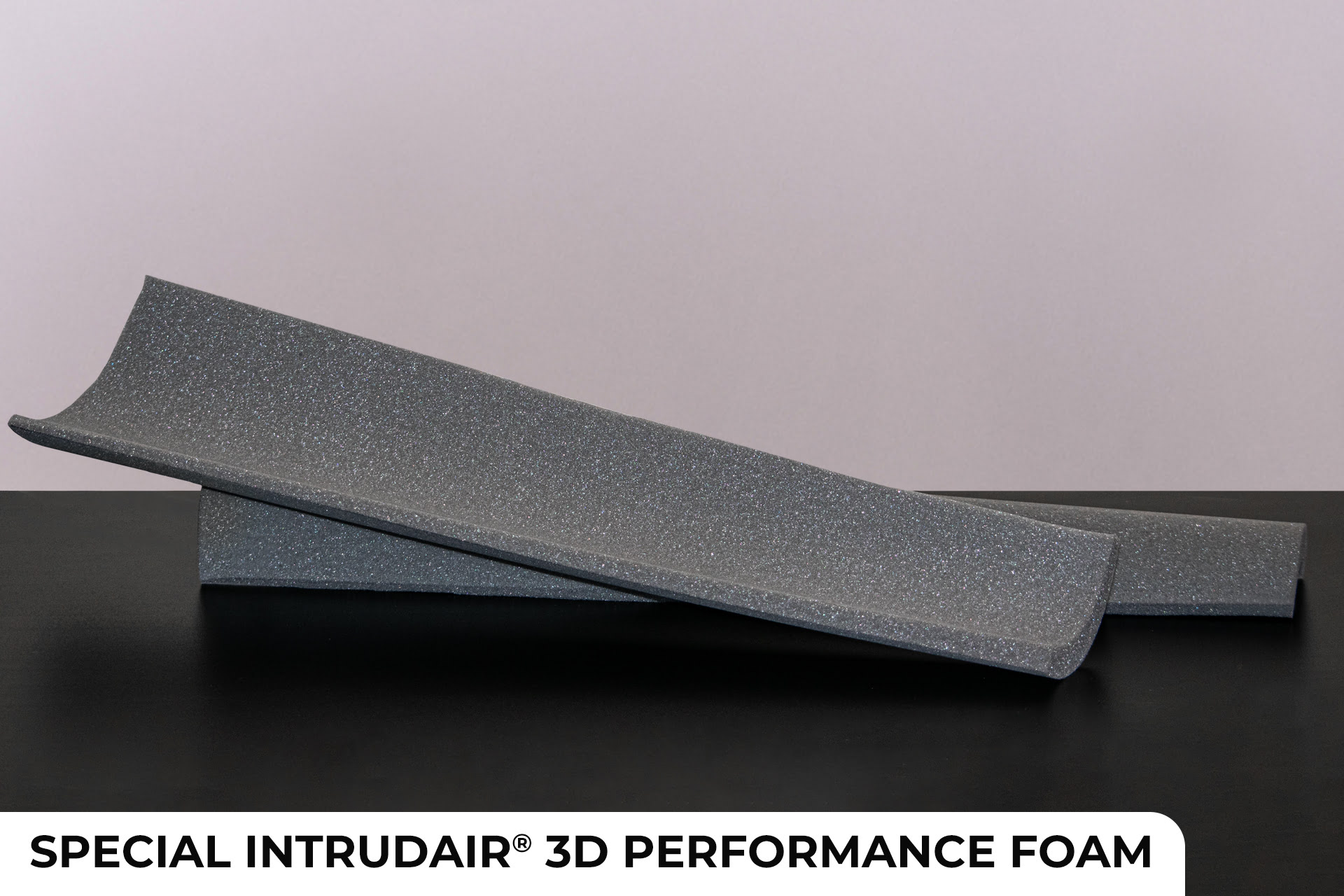

BOOTIE:

The bootie is responsible for stability. Intrudair is the only company to use a bootie-fix system developed to fix the bootie in place. This system prevents the bootie from deforming during flight. The fixed shape provides extra stability and easy manoeuvrability, and the width of the stride can be adjusted when the bootie is opened.

At the moment we believe that the well-tuned wing profile, pressure and stabilisation give the main flight parameters of our suits, which make Intrudair suits more stable and easier to fly than their competitors.

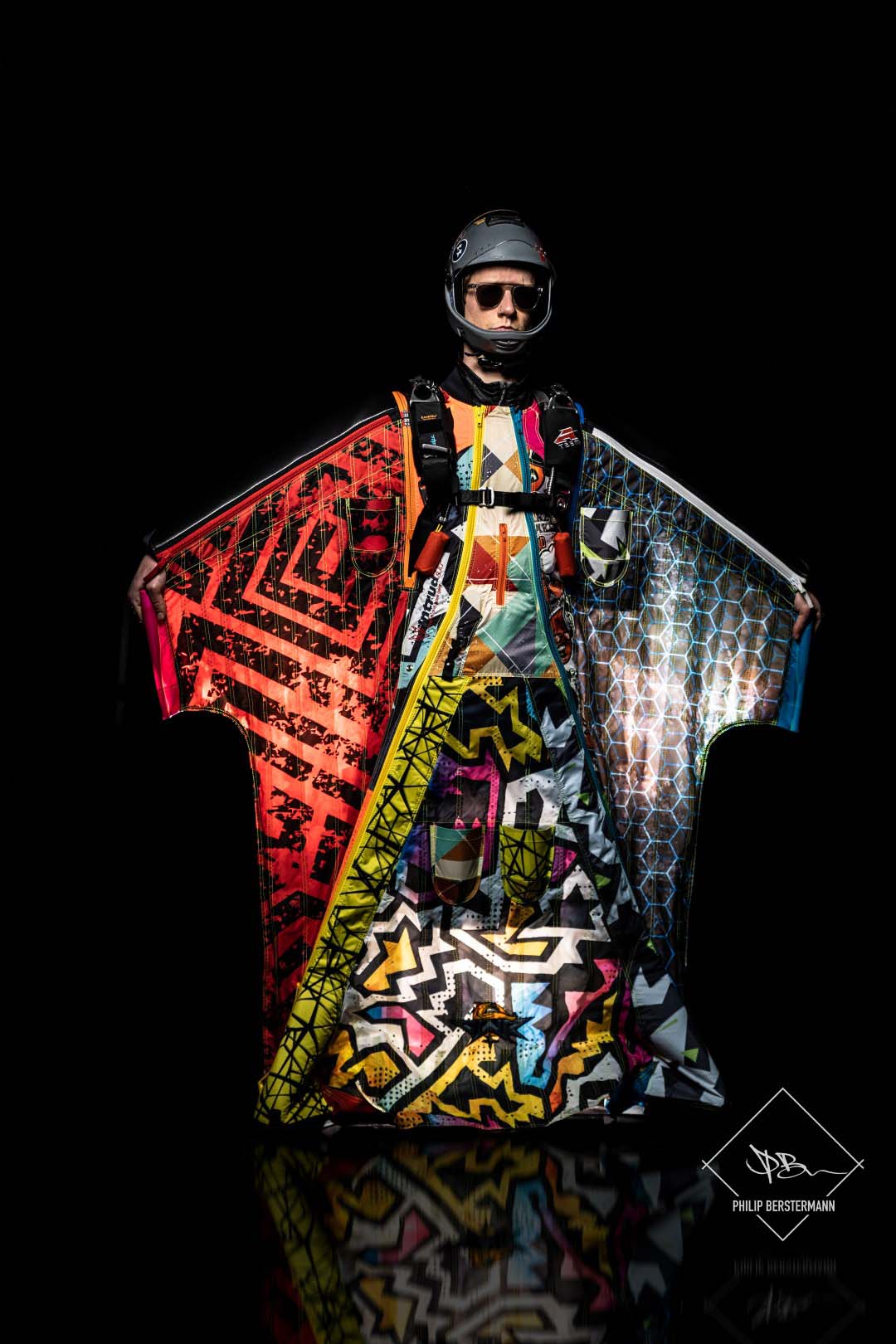

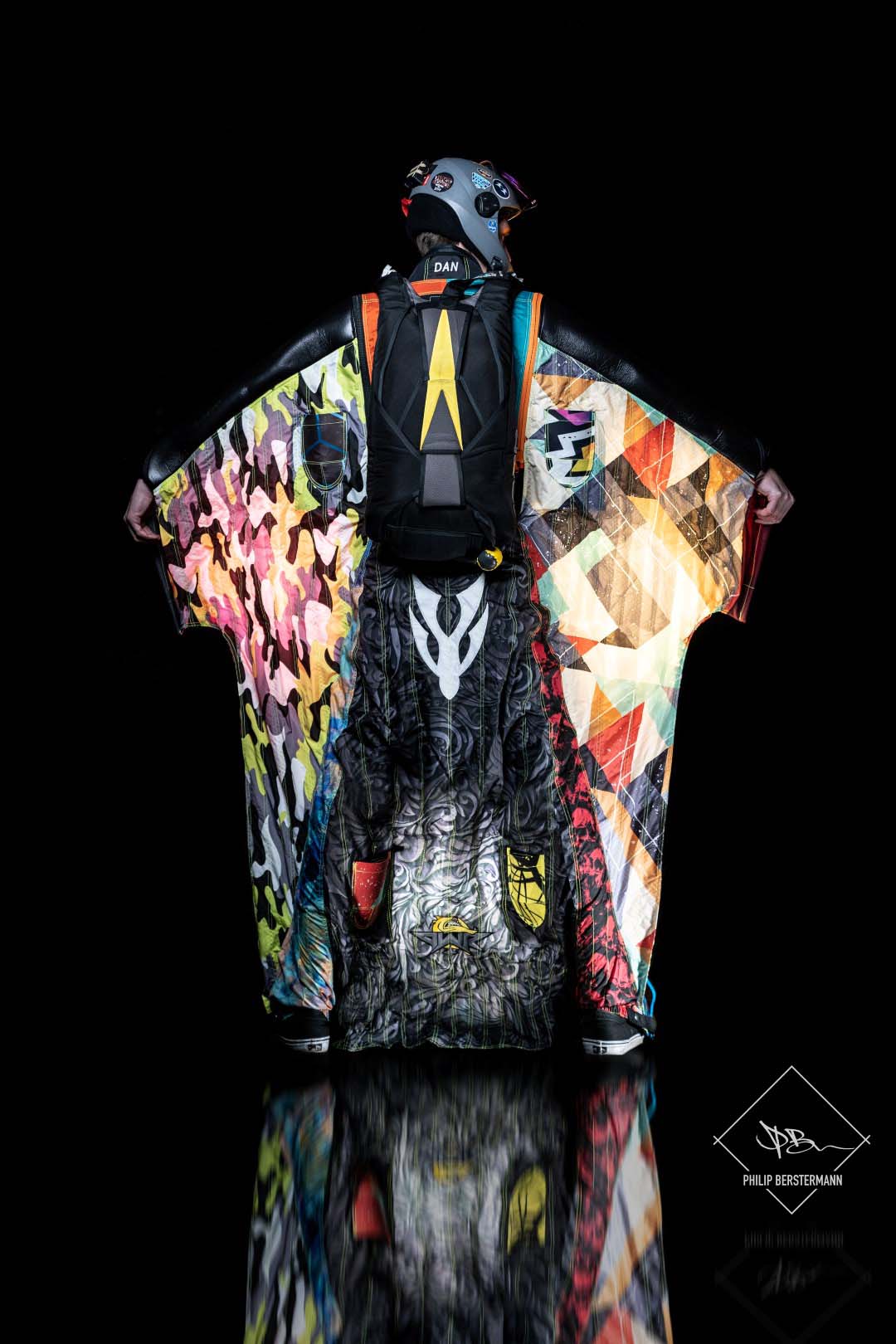

ARTWORK:

Intrudair puts a special effort into the styling of the suits, for extra custom-designed suits we offer a graphic service that crosses the boundaries of artistic suit design!Our graphic designers can create patterns on your suit that are almost unimaginable. They match and align the graphics to the over 50 printed parts of the suit. This work is very time consuming and requires full manual work, no automatic program or pattern zooming software can do this.

For normal prints the fabric is printed in rolls and cut out, for super custom prints a "blown" image is edited onto the desired design and then proofed several times before cutting. After that, thanks to the handwork of the seamstresses, almost all the patterns fit and so there are some patterns where you will only find the air vents after a long search. These all add to the length of the process but in the end you will have a truly unique, personalised and custom-designed wingsuit.

ZERO WASTE:

We pay attention to environmentally conscious manufacturing. The leftover printed materials are used in the Zero waste project so the plastics don't end up in the trash but start a new life in an extra cool customized outfit.Why is Zero waste more expensive?

Sure, the materials are leftovers but cutting the dress nearly becomes a manual operation. Each printed part is put one by one under the laser cutter in an effort to use up all the scraps, so the extra cost of printing is invested in manual labour. We use the scraps and save nature with extra working hours.

Processing.. Please Wait!